The Oswego Iron Furnace, built in 1866 at the confluence of Oswego Creek and the Willamette River, just south of Portland, was the first iron furnace on the Pacific Coast. Between 1867 and 1885, it produced 42,000 tons of pig iron, sold as Oregon Iron to foundries in Portland and San Francisco. Located in present-day George Rogers Park in Lake Oswego, the furnace is Oregon’s oldest industrial landmark and is listed on the National Register of Historic Places. It is the only surviving charcoal blast furnace west of the Rocky Mountains.

Before 1867, virtually all iron on the West Coast was brought by ship around Cape Horn, a hazardous 17,000-mile voyage that took four to five months. Imported products such as pig iron, were sold for up to ten times what they cost in the East. The discovery of iron deposits near Oswego in 1861 excited hopes that Oregon could supply most of the demand for iron on the Pacific Coast. Oswego also had timber for charcoal fuel, a river landing on the Willamette, and waterpower from the outflow of Sucker Lake (now Oswego Lake).

The Oregon Iron Company was founded in 1865 by a group of Portland merchants whose interests in shipping, railroads, water systems, and real estate shaped the future of Portland as the cultural and economic center of Oregon. Iron was a resource essential to their vision of a commercial empire in the Pacific Northwest. William S. Ladd was elected president of the company, H. C. Leonard was vice-president, and Henry D. Green was secretary.

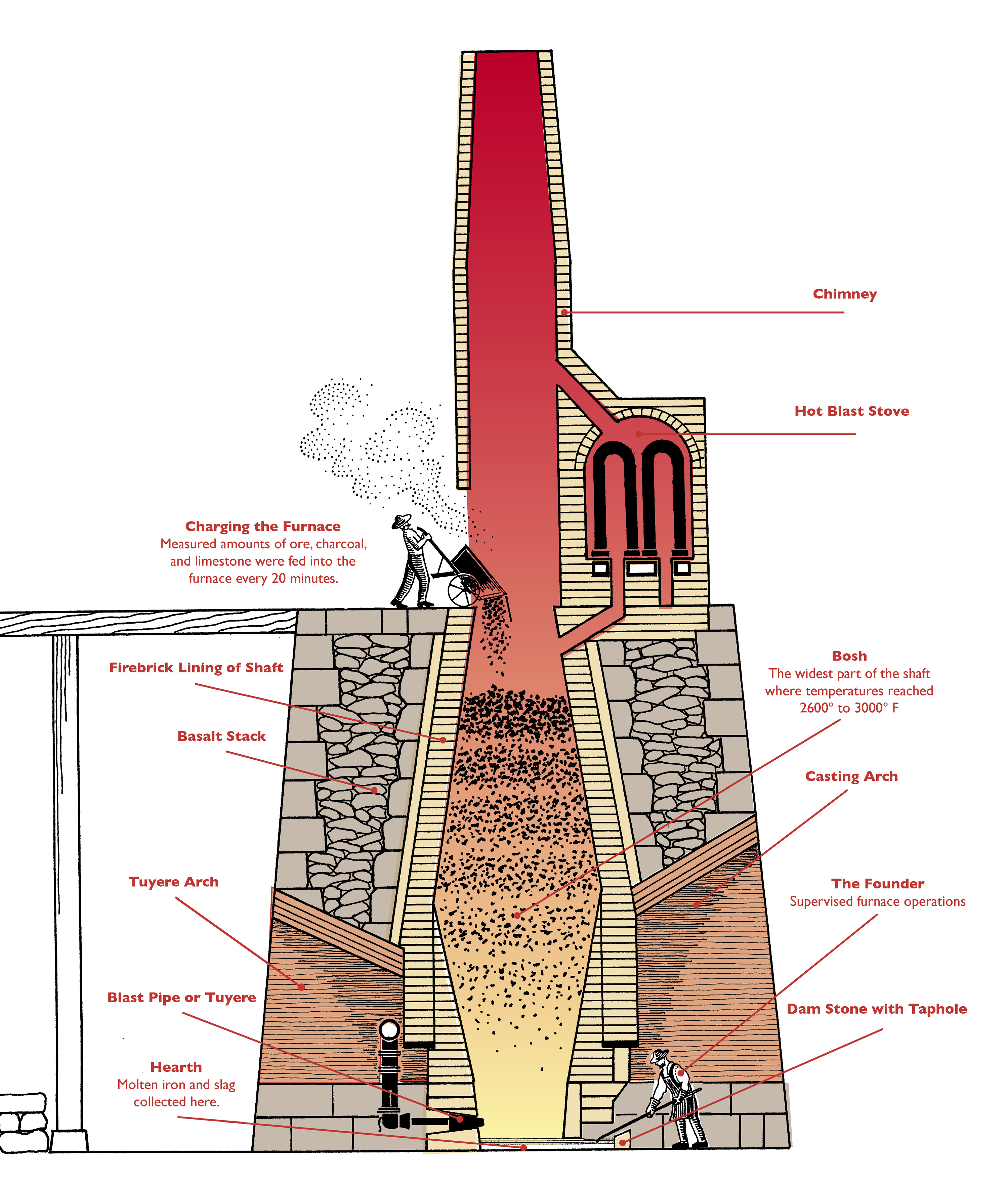

Construction on the furnace began in 1866, supervised by George D. Wilbur of Sharon, Connecticut. Wilbur modeled the stack, as stone furnaces are called, on the furnaces of the Barnum Richardson Company in Lime Rock, Connecticut. The thirty-two-foot stack is shaped like a truncated pyramid with gothic arches piercing its four sides. The massive walls were built to withstand temperatures of 2,800°F. Payrolls show that forty-two quarrymen, masons, and carpenters were engaged in construction. Basalt for the stonework was quarried from a ledge on the north side of Sucker Lake. Firebrick for the shaft, the chimney, and the heat exchanger was imported from Britain. A large complex of buildings surrounded the furnace.

The furnace was “blown in” on August 22, 1867, amid high hopes that Oswego would become the “Pittsburgh of the West.” Charcoal, ore, and limestone were fed into the top of the shaft, and air was injected into the bottom through three ports in the smelting chamber. Molten iron was tapped through the casting arch. The first iron was cast on August 24, 1867. When the tap hole was opened, a stream of incandescent iron poured down a channel and filled a series of molds in the sand floor of the casting house. The ingots have been called pig iron since at least the mid-seventeenth century because the layout of trenches reminded workers of a sow nursing piglets.

Ore for the furnace, which averaged 44 to 54 percent iron, was obtained from two mines: a small mine south of the lake and a large underground mine on Iron Mountain on the north side of Oswego Lake. Charcoal production was the most expensive part of the business because it involved almost half the work force. By 1885, there were over a hundred charcoal pits smoldering in the woods between Tryon Creek and West Linn.

Throughout its history, the Oregon iron industry was undercapitalized and struggled to compete with less expensive Scottish pig iron as the tariff on imports was repeatedly reduced. Skilled workers were scarce, so labor costs were high. In 1877, the bankrupt company was sold at a sheriff’s auction to a group of experienced iron makers from Ohio led by Lamar B. Seeley and Ernest W. Crichton. They incorporated the Oswego Iron Company on March 9, 1878, and made a number of improvements, building a railroad from the mine to the furnace, increasing the company’s timber holdings, and remodeling the stack by adding 12 feet to its top. To finance the improvements, they borrowed heavily from businessman Simeon G. Reed. Four years later, they accepted Reed’s offer to buy the company.

The Oregon Iron & Steel Company was incorporated on April 2, 1882, with Reed as president. With financial support from railroad financier Henry Villard, Reed embarked on ambitious plans to build a modern cupola blast furnace half a mile north of the original works. The old furnace was blown out for the last time on November 1, 1885. After many delays due to Reed’s difficulty in securing financing, the new furnace was blown in on October 20, 1888. The company quickly set new records, producing 12,305 tons of pig iron in 1890 and employing over 600 workers. The success was short-lived.

The company’s dependence on expensive charcoal fuel and the cost of importing limestone from Washington State were major factors in the demise of the Oregon iron industry, but the fatal blow was the Panic of 1893, one of worst financial crises in U.S. history. Unable to operate without credit, Oregon Iron & Steel was one of 14,000 businesses that failed following the crash. The company’s pipe foundry continued to manufacture water pipe until 1928. Both the pipe works and the ironclad furnace were dismantled in 1929, but the old furnace survived because its stonework defied demolition.

The City of Oswego purchased the original furnace site for a public park in 1945. Sixty years later, concerns about the condition of the furnace prompted the city to create a Furnace Restoration Task Force. After seven years of research and planning, work to preserve and stabilize the stack was completed in 2010. The furnace is now the centerpiece of the Oswego Iron Heritage Trail, and its legacy is preserved in Portland’s cast iron buildings, erected by iron company owners W.S. Ladd, Henry Corbett, Addison Starr, Henry Failing, M.S. Burrell, Simeon Reed, and J. Frank Watson.

-

![]()

Oswego Furnace 2010.

Courtesy Susanna Kuo

-

![]()

Oswego Furnace under construction in 1866.

Courtesy Lake Oswego Public Library Local History Collection 770b

-

![Photo by Carleton E. Watkins]()

Oswego Iron Works 1867.

Photo by Carleton E. Watkins Courtesy Oregon Historical Society Research Library OrHi 21596

-

![Photo by Carleton E. Watkins]()

Oswego Iron Works 1867.

Photo by Carleton E. Watkins Courtesy Oregon Historical Society Research Library OrHi 21593

-

![]()

Oswego Iron Works c. 1874.

Courtesy Lake Oswego Public Library Local History Collection 165

-

![]()

Oswego Furnace Cross Section.

Illustration by Susanna Kuo

-

![]()

Casting pig iron at the Oswego Furnace.

Illustration by Susanna Kuo

-

![]()

Oswego Furnace c. 1908.

Courtesy Lake Oswego Public Library Local History Collection 3342

-

![]()

Oswego Furnace c. 1908.

Courtesy Lake Oswego Public Library Local History Collection 2289

-

![Scaffolding encloses the furnace]()

Aerial view of Oswego Furnace during 2009 preservation.

Scaffolding encloses the furnace Courtesy City of Lake Oswego

-

![]()

Oswego Furnace 2010.

Courtesy Susanna Kuo

-

![]()

Oswego Furnace and Interpretive Kiosk 2012.

Courtesy Susanna Kuo

Related Entries

-

Cast iron buildings in Portland

Portland is home to the second largest collection of cast iron architec…

-

![Ladd Estate Company]()

Ladd Estate Company

The Ladd Estate Company played a major role in the residential developm…

-

![Lake Oswego]()

Lake Oswego

Lake Oswego is a suburban city located eight miles southwest of Portlan…

-

![Oregon Iron & Steel Company]()

Oregon Iron & Steel Company

The Oregon Iron & Steel Company (OI&S;) was incorporated in the town of…

-

![William S. Ladd (1826-1893)]()

William S. Ladd (1826-1893)

At age twenty-seven, William Sargent Ladd was the youngest mayor to eve…

Related Historical Records

Map This on the Oregon History WayFinder

The Oregon History Wayfinder is an interactive map that identifies significant places, people, and events in Oregon history.

Further Reading

Daniels, Joseph. Iron and Steel Manufacturing in Washington, Oregon, California, and Utah. Seattle: Univ. of Washington Engineering Experiment Station Series, report no. 2., 1929.

Hergert, Herbert L. “Early Iron Industry in Oregon.” Reed College Bulletin 26:2 (Portland, OR: Reed College, 1948).

Kuo, Susanna and Rick Minor. “The Oswego Furnace: Industrial Archaeology at the First Iron Works on the Pacific Coast,” IA: The Journal of the Society for Industrial Archaeology 42:1, 2018.